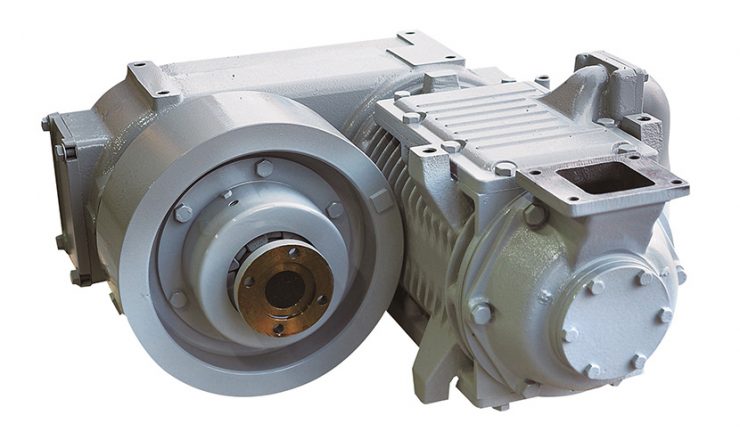

The world's first Wing Compressor

is the symbol of Hori Engineering’s technological capability.

The wing swings left and right.

Gas is sucked in and compressed by changing the volume.

This simple configuration enables high efficiency.

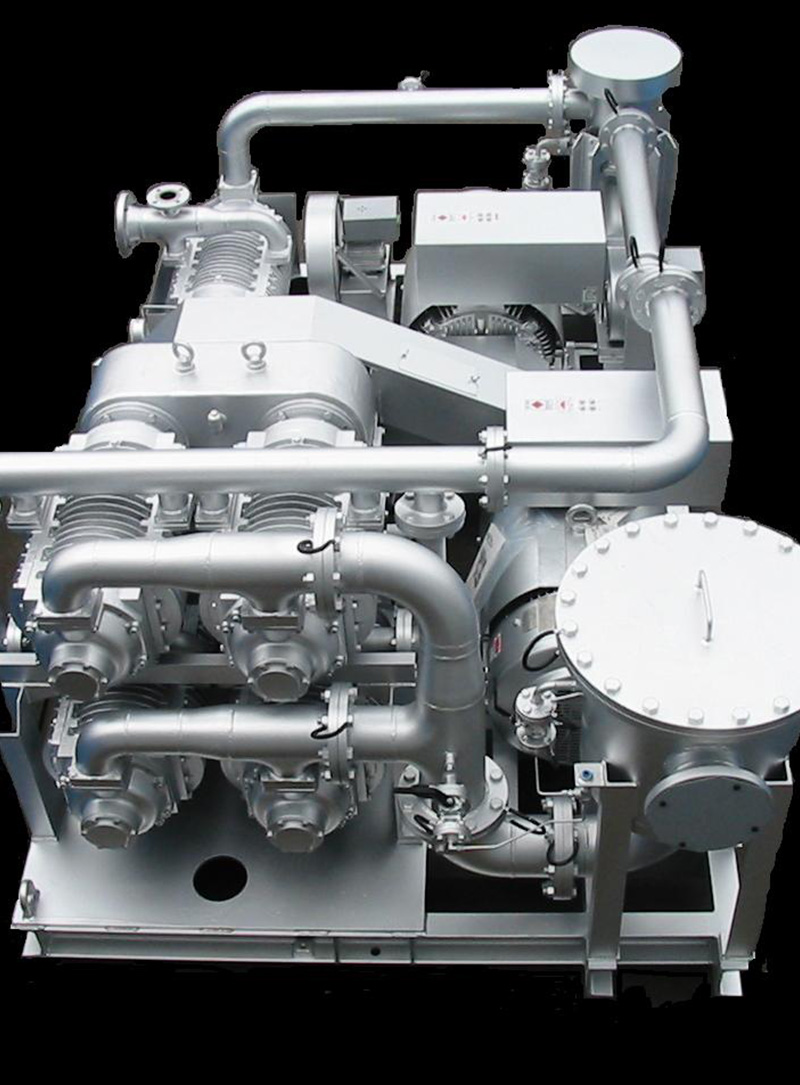

High quality, long life, low price

A 60-year history of custom-made technology.

The ”Wing Compressor”, invented by our founder, Kohei Hori.

A revolutionary invention said to happen only once in a 100 years.

The products made by those who have inherited this unique Hori DNA are being well received by customers not only in Japan but from all over the world.

We can develop, design, and manufacture truly original, one-of-a-kind products that meet the wide-ranging needs of our customers.

The inherent faith we have in our technical capability means we are ready to accept any potential development risks we may face.

Our work philosophy attracts engineers who have a passion for manufacturing and an eagerness to develop truly unique products.

Our long-term aim is to create a clean society based on this unique Wing Compressor technology.

We aim to have Hori Wing Compressor distributors in more than 40 countries (currently 20 countries) to further enhance our support system,

and intend to establish ourselves as a top brand throughout the world.